Peter Lepper (†) founds the first company under the name TPS (Technitube Pipe & Steel) and starts trading and exporting tube & pipe products and accessories in Ratingen near Düsseldorf.

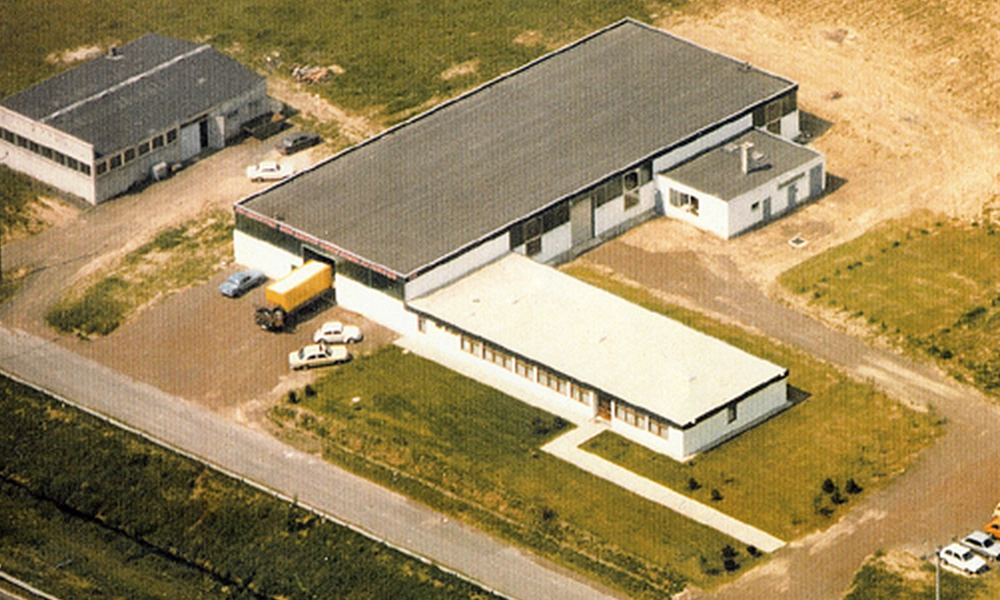

Construction of the first business premises and production facilities in Daun / Eifel. With the start of its own production activities, such as special threading, bending and drawing, the company enters the tube product processing industry.

Production of oilfield pipes begins under the name Oil Country Tubular Goods (OCTG). The new OCTG plant manufactures pipes for the oil and gas industry. The company name is changed to TPS-Technitube Röhrenwerke GmbH

The successful growth continues and the second TPS plant (stainless steel plant) starts production of seamless, cold-finished stainless steel and nickel alloy tubes with outer diameters in the range of 5.0 - 60.3 mm.

Fast and reliable when it comes to distribution as well: TPS expands its operations through the warehousing and distribution of tubes and tube accessories.

Extension of the Stainless steel plant with the addition of the fifth cold pilger mill. TPS becomes a major manufacturer in Germany of seamless cold-finished tubes made of stainless steel, nickel and titanium alloys.

At the stainless steel plant, a state of the art cold pilger mill as well as a high-performance tube cutting and deburring line are brought into operation while, at the same time, the capacity is doubled. Groundbreaking for the new OCTG mill.

Start of production of the new OCTG plant with a new upsetting machine and two new production lines for finishing. The stainless steel plant is certified according to automotive standard ISO/TS 16949:2002

Implementation of a second state-of-the-art bright annealing furnace in the stainless steel plant.

Commissioning of the 8th cold pilger mill in the stainless steel plant.

Implementation of a new state-of-theart ultrasonic testing device in the stainless steel plant.

Construction of the new administration building.

Successful participation in the initiative „CARBON REDUCED TUBES & PIPES – On the way to CO2-neutral steel tubes“ of the Wirtschaftsvereinigung Stahlrohre.

Artificial intelligence is making its way into the company and supporting processes in administration and production.

TPS celebrates its 50th anniversary

Please select your region to display the appropriate contacts.

With the introduction of our energy management system, we use energy more efficiently, identify and implement savings measures, and comply with current energy efficiency regulations.

For our customers, this means reliable processes, stronger competitiveness, and a partner committed to efficiency and responsibility.