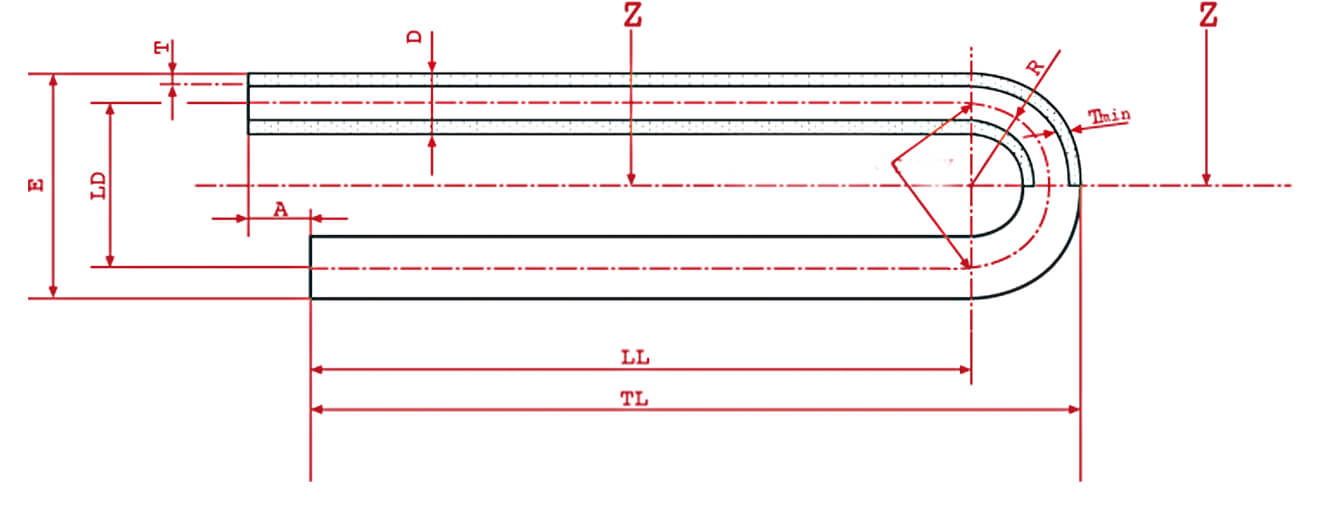

| Tolerance on radii Rt | rm 1,5 x da up to rm 200: +/- 1,0 mm rm > 200 up to rm 400: +/- 1,5 mm rm > 400 +/- 2,0 mm |

| Straight leg length difference a | Straight leg length ≤ 6000 mm: - 0 / + 3 mm Straight leg length > 6000 mm: - 0 / + 5 mm |

| Straight leg length tolerance l | Straight leg length ≤ 6000 mm: - 0 / + 3 mm Straight leg length > 6000 mm ≤ 9000 mm: - 0 / + 4 mm Straight leg length > 9000 mm: - 0 / + 5 mm |

| Total length tolerance lg | ≤ 6000 mm: - 0 / + 5 mm > 6000 mm: - 0 / + 8 mm |

| Flattening of the bent area | Acc. TEMA RCB-2.31: max. 10% flattening from the nominal OD |

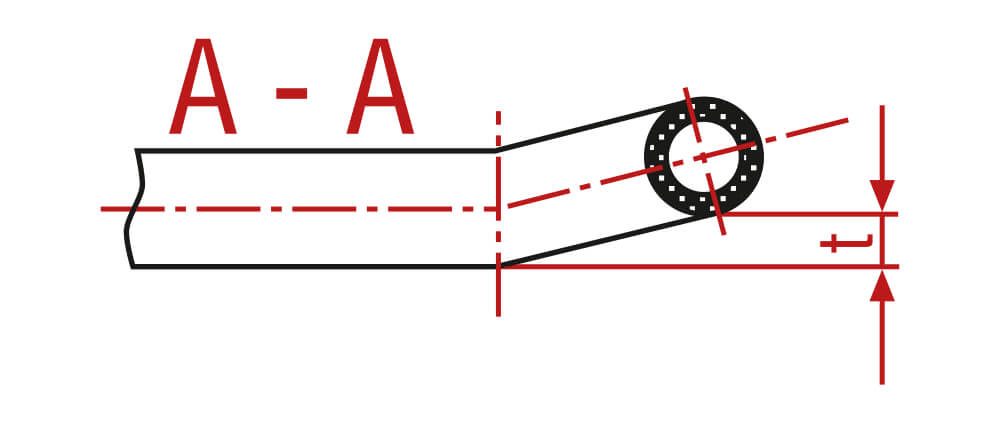

| Deviation from the roundness R [%] |

rm ≤ 4 x da:

Calculation of the ovality: |

| Wall thinning of the bent area Smin | Acc. TEMA R-2.31 for radii larger than 1,5da: max 17% wall thinning |

| Flatness tolerance t | rm ≤ 300 mm: ≤ 1,5 mm rm > 300 mm: ≤ 2,0 mm |

| Deviant tolerances | With radii <1,5 x da tolerances deviating from the tolerance standard Bending of titanium/titanium alloy U-tubes is possible for radii 2 x da |