Grafic: ©️ SMS group

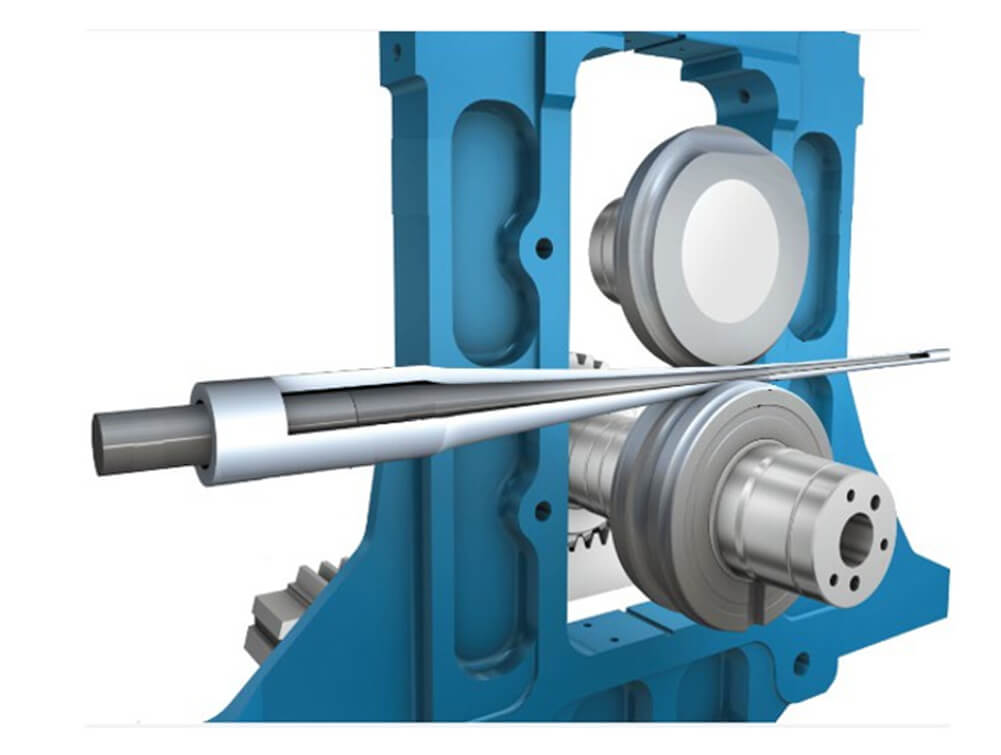

The cold pilger rolling process is a cold forming process in which the initial tube, the so-called hollow bar, is moved through a fixed mandrel tapering according to the input and output dimensions of the process.

During this process, the tube is rolled longitudinally through the mandrel by two rolls moving forward and backward with a corresponding pre-set outer contour. In the two dead points of the movements, the tube is free, turned and pushed forward in order to obtain an even, high-quality, round surface and a constant forward motion.

This means that a smaller, longer tube with tighter tolerances and a good surface finish is produced form a larger tube.