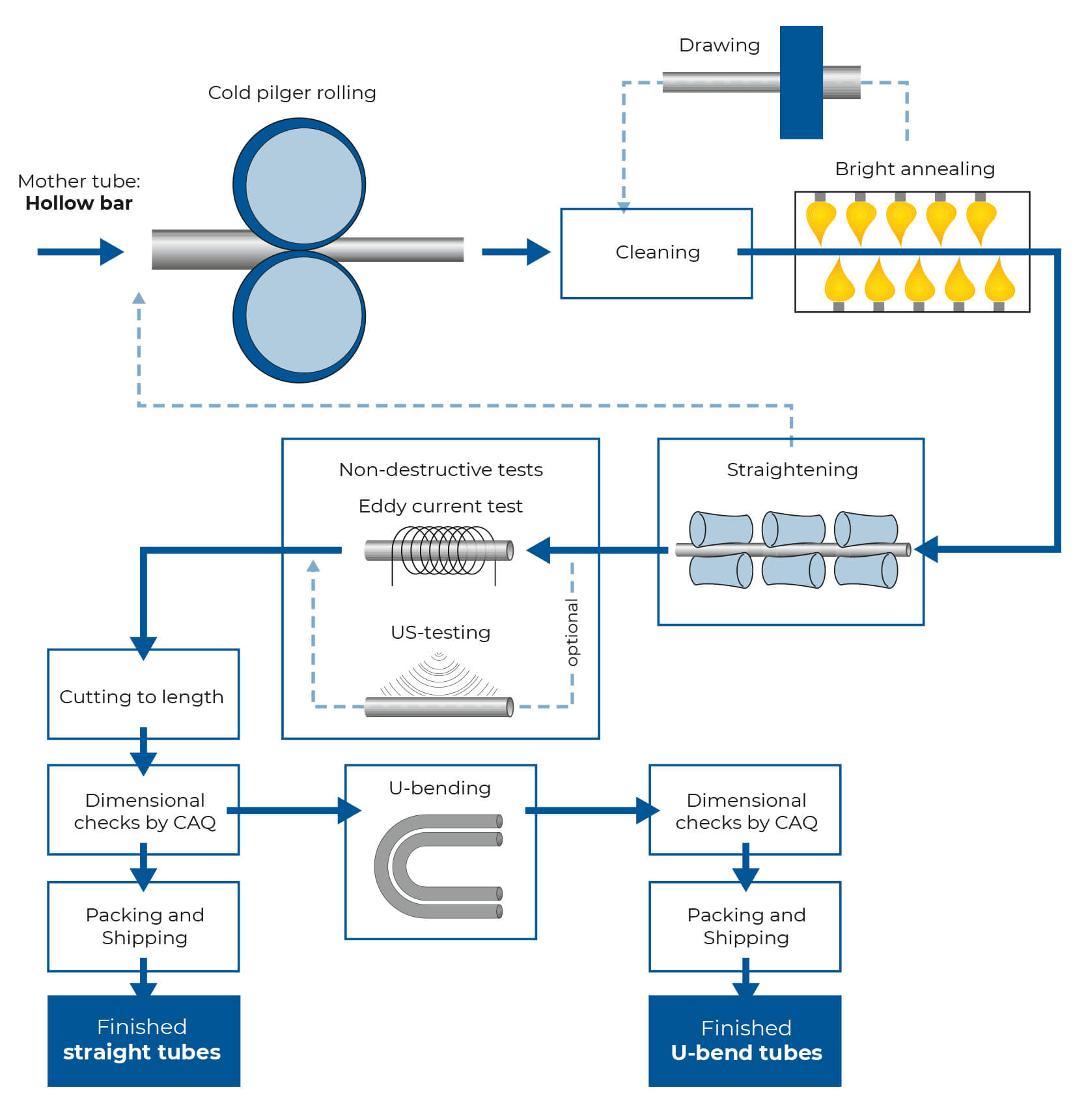

The Production process in the INOS mill starts with the so-called hollow bar which is formed to the desired final size in the cold pilger process. The pilgered tubes pass through a cleaning process and are bright annealed afterwards. This process allows the production of tubes with an extremely good surface quality. After the heat treatment, the tubes are straightened and, depending on the final dimension, are formed again

through pilgering or drawing. The straightened tubes are 100% eddy-current tested. On the customer’s request, an ultrasonic test is also possible. Finally, the tubes are cut to length, the dimensional and visual inspection is carried out and the straight tubes are packed and delivered. Bending into U-tubes is also possible.